November 12, 2023

From Classroom to Clouds: Our Journey in the SAE AeroDesign Competition

Embarking on an ambitious venture, my team of Aeronautical international master students at Linköping University set out to conquer the skies by designing and constructing an aircraft named “Findus.” This thrilling journey unfolded over three months as part of our master’s program course titled “Prototype Realization.” Our diverse team, comprising three dedicated students ( Me :D, Albert and Natalie) , collaborated seamlessly throughout this exhilarating project.

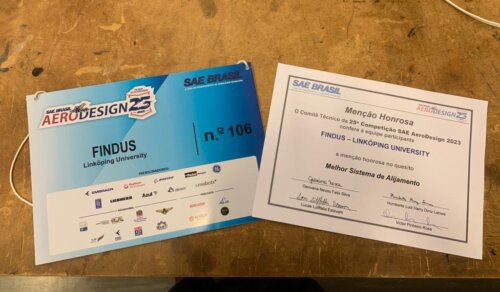

With additional support from our peers in the program, we were able to design and build our aircraft from scratch and participate in the SAE Aero-design competition that was held in Brazil from 2ed of November till the 5th November where we won the Second place in the competition. Recognizing our passion and potential, Linköping University and SAAB provided our team with funding for our journey to Brazil. Be able to build the aircraft in a a professional and successful way, we had to pass through Stages of Findus’ Creation:-

- Literature Review and Research: Delving into existing knowledge, we conducted an in-depth exploration of aircraft design principles, aerodynamics, and competition requirements. This stage set the foundation for our project.

- Concept Design: Applying our research, we conceptualized the initial design of Findus. This phase involved sketching ideas, considering aerodynamic efficiency, and ensuring feasibility within competition parameters.

- Sizing: Precise calculations and sizing considerations were crucial to determine the optimal dimensions for Findus, ensuring a balance between weight, lift, and overall performance.

- Material Selection: Choosing the right materials was critical for both structural integrity and weight optimization. This stage involved extensive research on material properties and their suitability for our aircraft.

- Weight Estimation: Accurate weight estimation was essential for performance predictions. This stage involved meticulous calculations based on chosen materials, structural design, and component weights.

- Aerodynamics, Stability, and Performance Analysis: Leveraging advanced software, we conducted comprehensive simulations to analyze the aerodynamics, stability, and overall performance of Findus. This stage guided adjustments to enhance efficiency.

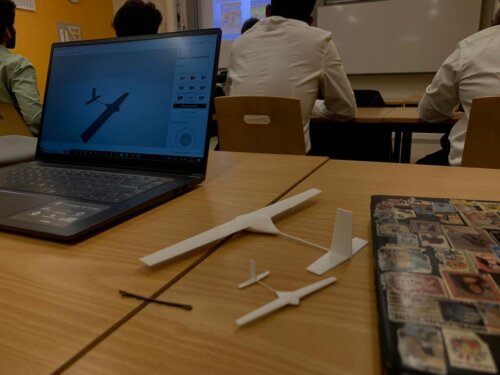

- Manufacturing Process: Transitioning from theory to reality, we initiated the manufacturing process. This hands-on stage involved fabricating components, assembling the aircraft, and conducting quality checks.

- Flight Testing: With the prototype ready, we conducted rigorous flight tests to validate our design assumptions. Real-world data gathered during this stage was invaluable for fine-tuning Findus for optimal performance.

- Competition: The culmination of our efforts led us to the SAE AeroDesign Competition in Brazil. Findus competed on an international stage, and were able to win the second place after three successful flight and despite that it was the first time for any team from the university to join the Competition. So starting from zero accumulated knowledge, and representing Liu university and Sweden, it was a great achievement and win for us

.

The journey of building Findus epitomizes the fusion of theoretical knowledge with hands-on experience, illustrating the power of collaboration, innovation, and determination. As we soared through the clouds in Brazil, we not only competed but showcased the spirit of international student excellence in aerospace engineering at Linköping University. The skies are no longer a limit; they are our canvas for future innovations.